Elastomers Applications

Every day, we depend on a wide variety of products and materials to go about our daily lives, many of which we barely notice. One example is the elastomer — this material has become essential in numerous industries and applications. From the tires on our cars and the containers for our food to the seals and parts used in industrial equipment, elastomers are an essential part of daily life in the modern world. Despite this, many people are unaware of what elastomers are, what makes them important and how extensively they are used throughout multiple industries.

What Are Elastomers?

Most people are familiar with elastomers under the name "rubber," though this conjures a very loose idea of elastomers' properties and applications. At a chemical level, elastomers are long-chain polymers of carbon, hydrogen, oxygen and silicon whose chemical structures have intermolecular crosslinks. These chemical properties result in materials that are both viscous and elastic.

A simple way to visualize this is as a ball of knotted strings. Each string represents a polymer chain, and the knots tying the strings together represent the crosslinks. When pulled under stress, the strings will easily stretch out in the direction of applied force, but the crosslinks will keep them together. When the stress is removed, the crosslinks ensure that the elastomer returns to its original configuration. Without the long strings or crosslinks, applied stress would result in a permanent deformation in the material.

The exact properties of elastomeric materials depend on how many polymeric crosslinks there are, how strong they are and how they're distributed in the material. Depending on their specific chemical structure, elastomers fall into two primary classifications:

- Thermoset elastomers are elastomeric materials that do not melt when heated. These are the most common type of elastomer. Thermoset elastomers usually require vulcanization, which is a chemical curing process that forms crosslinks in a polymer chain to increase the rigidity and durability of rubber products.

- Thermoplastic elastomers are elastomers that melt when heated because their crosslinks are significantly weaker, allowing the material to melt and reform without losing its elastomeric properties at operating temperature. These elastomers are generally easier to use in manufacturing, are more easily recycled and exhibit a greater ability to stretch than thermoset elastomers.

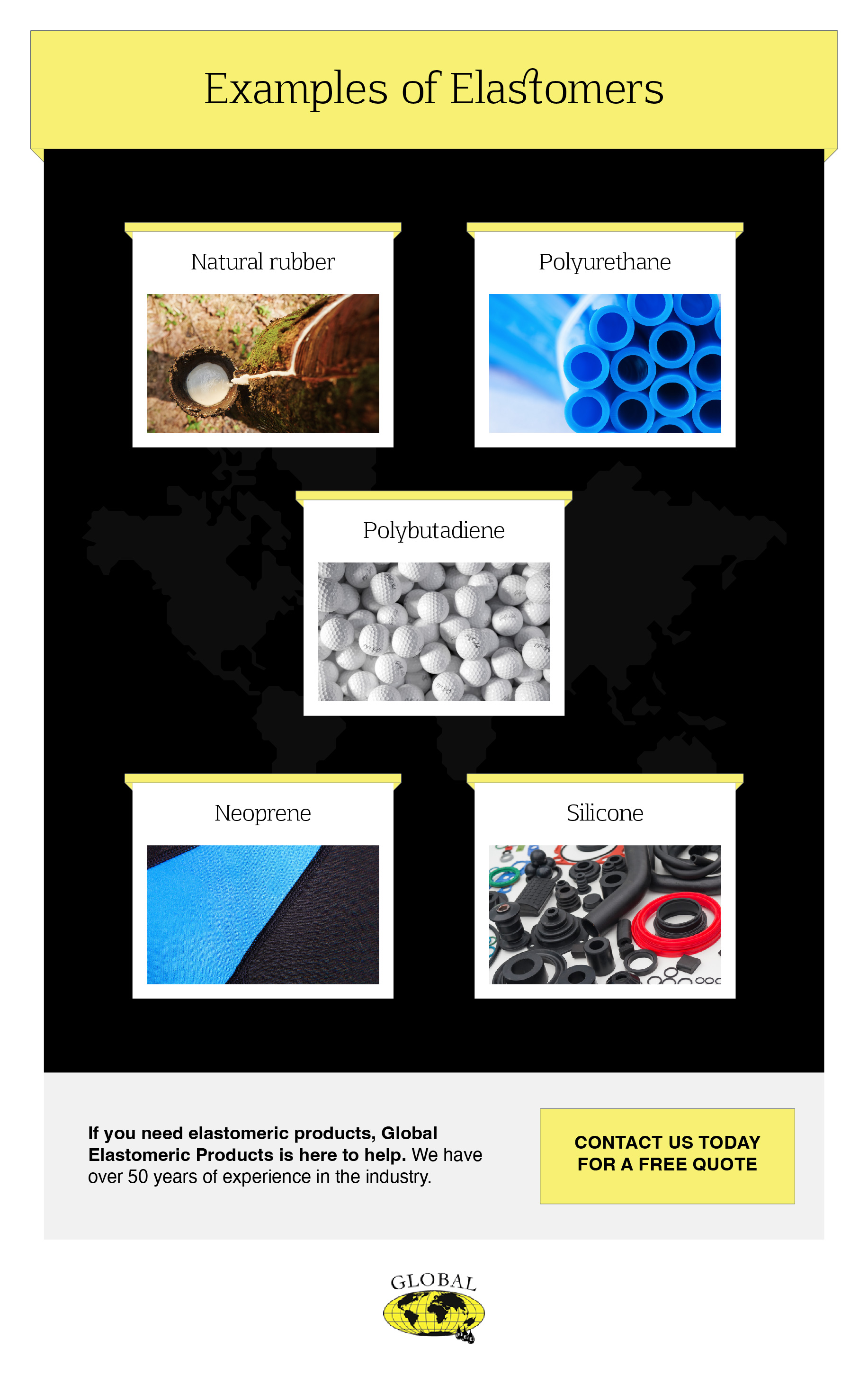

Some examples of elastomers include natural rubber, polyurethane, polybutadiene, neoprene and silicone, among others.

Properties of Elastomers

Though many people think of rubber as a bouncy, flexible material, rubber materials vary in physical properties depending on their specific type and chemical makeup. The two most essential features of elastomers, however, are viscosity and elasticity, described in more detail below:

- Viscosity is the ability of a substance to flow. The level of viscosity of a liquid determines how quickly or slowly it flows under force. For example, when pouring oil versus water from a glass, oil has a noticeably slower flow than water, meaning that it is more viscous. Elastomers are generally very viscous, making them slow-flowing under force.

- Elasticity is the ability of an object to return to its original shape after stretching or compressing it under force. A simple example is a rubber band — if you stretch a rubber band, it snaps back to its original form. Elastomeric polymers tend to exhibit a high level of elasticity, making them more resistant to breaking or cracking. In fact, elastomers can reversibly extend up to 700% depending on the specific material.

On top of these properties, elastomeric materials are also generally insoluble, can swell in the presence of certain solvents and have a low creep resistance. Some elastomers are resistant to heat and environmental conditions like humidity and steam. Thermosetting elastomers also can not melt but instead pass into a gaseous state.

Applications of Elastomers

Because of their unique properties, elastomers are used in a huge range of industries in a variety of applications. The following are just a few types of elastomers and how they are used in various industries:

- Natural rubber: Consisting of the organic compound isoprene derived from the rubber plant, natural rubber is highly elastic and strong, but is susceptible to aging and swelling in the presence of oil, making it less ideal in the production of seals. Natural rubber is most commonly used to produce automotive products, wearable items like footwear and rubberized fabrics, latex products and anti-vibration materials.

- Polyurethanes: Polyurethanes are extremely versatile in manufacturing, able to provide tough, reliable results. Generally, polyurethanes are used extensively in the textile industry to produce elastic clothing like spandex. However, thermoplastic polyurethanes are also used to manufacture shoes, cushions, cables, seals and technical parts.

- Polybutadiene: In combination with other rubbers, namely natural rubber or styrene, polybutadiene is an essential elastomer, especially in the production of automotive tires.

- Neoprene: This synthetic rubber is highly resistant to degradation, and is very well suited in the production of corrosion-resistant gaskets, hoses and coatings. Most famously, however, neoprene is used in wetsuits.

- Silicone rubber: Silicone is different from other elastomers, consisting of primarily silicon and oxygen rather than carbon and hydrogen atoms. More resistant to extreme temperatures, aging and environmental factors, silicone is a great general-purpose elastomer that is commonly used in automotive, aerospace, medical, food production and consumer product applications.

These elastomers and more are used across several industries in various applications.

1. Oil and Gas Applications

Synthetic elastomers made from petroleum products are used throughout the oil and gas industry in a variety of essential applications. Some examples include:

- Seals: Hydraulic seals are commonly used in the petroleum industry to prevent leaks, making them essential to petroleum plant functionality. Some examples include rubber seals for storage tanks and gate seals for hydroelectric dams.

- Hoses: Hoses move oil from one place to another, and are commonly made of elastomers for maximum flexibility.

A large variety of other petroleum plant parts are also made with rubber parts. A few examples include packer cups, stripper rubbers, pipe wipers, gaskets and bladders, as well as custom rubber products. For a better idea of what's available, visit the Global Elastomeric Products products page to see our high-quality products for the oilfield industry.

2. Automotive Applications

Elastomers are used in the production of many of automotive products, including the following:

- Tires: Tires are made with a variety of synthetic and natural elastomeric materials, which help give them excellent flexibility and durability on the road.

- Seals and gaskets: Automotive gaskets and seals, including radiator seals, are commonly made of elastomers for their ability to effectively seal and protect parts regardless of environmental factors.

- Vibration dampening: Elastomer materials are used to reduce vibration and noise in many applications, including the automotive industry. For example, elastomer mounts are used to prevent fans from transferring vibrations to the surrounding structure.

- Windshield wipers: Wipers are made of elastomers, which can effectively mold to the curvature of the windshield to remove water and debris.

Elastomers are also commonly used as adhesives and mounts in vehicles, sealing and securing windshields, mirrors and other vehicle features. They're also essential in suspension systems, engine mounts, belts and hoses.

3. Industrial Applications

Depending on the specific plant, elastomers are used in a wide range of industrial applications, including:

- Seals: Sealing rings are used in a vast range of industrial applications, and are typically made of elastomers. Thermoset rubber seals are more traditional, but thermoplastic elastomers are becoming more common because they can be produced faster.

- Conveyor belts: Belts and belt parts are commonly made of elastomers for their ability to resist deformation over long periods of applied stress.

- Insulation: Electrical insulation is an important part of any manufacturing operation and is usually made of high-quality elastomers.

Elastomers are also used for floor coverings, hoses, tubes and drive belts. On top of all this, elastomers are commonly produced as industrial and engineering goods, making them even more ubiquitous in the industrial sector.

4. Agricultural Applications

The agricultural industry uses elastomers at every step, from herd management to food production. Some common applications include:

- Animal tags: Animal tags are often made of high-quality elastomers that are resistant to wear and weather damage. This is essential for herd identification and management.

- Conveyor belts: Belts are often used to move food through production, and the belts and associated parts are primarily made of durable elastomers.

Elastomers are also used in agricultural equipment. For example, elastomers make up the gaskets, seals, hoses and dampeners that are used in tractors and other agricultural vehicles.

5. Medical Applications

Healthcare facilities use a huge variety of elastomers at every level. Elastomers are often chosen for sterility, biocompatibility and low leaching levels. Some common examples include:

- Gloves: Latex is made of natural rubber, and these gloves are extremely common in the medical field, able to provide a barrier between caregiver and patient to maintain sterile conditions. Non-latex gloves are also made of elastomeric materials.

- Implants and prosthetics: Implants and prosthetics are often made of medical-grade elastomers, making use of the material's flexibility to achieve specific results. For example, certain implants require some amount of flexibility for comfort, while prostheses often need soft-touch elements to improve results in daily use.

Other examples of elastomers in the medical field include catheters, diaphragms and tubing.

6. Printing Applications

3D printing is often based around thermoplastic elastomers. Many 3D printers use thermoplastic elastomers as the substrate material for printed products, and other elastomers are being explored as possibilities for future applications.

The important part about this application is that it can be used for practically any of the industries previously mentioned. 3D printing can make custom parts for industrial, medical, agricultural and consumer applications with the right material and design.

7. Other Applications

The industries listed above describe only a few of the potential applications for elastomers. These materials are also commonly found in products people use in their daily lives. Here are some examples:

- Consumer products: Many consumer items are made with elastomeric materials, including raincoats, sponges and even pencil erasers. Many durable yet stretchy materials are also made with some type of elastomer-based textile.

- Footwear: Elastomers are extensively used in footwear applications. Polyurethanes and natural rubbers allow for excellent flexibility, allowing footwear to move with the wearer, while also cushioning the feet and joints from impact. Additionally, some elastomers can be manipulated more freely, allowing for greater design freedom for footwear companies to keep up with current trends.

- Sporting goods: Many sports items, including golf balls, bowling balls, footballs and protective equipment, are made of elastomers. Much of this has to do with the flexibility and shock absorbing capabilities of elastomeric materials.

- Food storage and delivery: Various food storage and delivery systems are made of elastomers. For example, bottle cap liners, liquid delivery tubes and baby bottle nipples are all made of elastomers. Bottle cap liners are often made of thermoplastic elastomers and serve as seals to protect the contents of the bottle from the outside world. Liquid delivery tubes and baby bottle nipples, on the other hand, are commonly made of silicone for its resistance to wear and its ability to be easily sanitized. Food-grade elastomers are also widely used to produce plates, storage containers and soft grips for baby utensils, among other food-related items.

- Housing: Many elastomers are used in the production of various construction components. For example, coolant and air conditioning hoses are commonly made from elastomeric polymers, as are certain types of insulation, roofing sheets and window profiles. In areas with seismic activity, elastomers are also used to create bearings to help buildings survive earthquakes.

- Adhesives: Elastomer adhesives are used in a huge range of industries for their efficacy, flexibility and resistance to wear.

The key to achieving the capabilities of elastomers, however, is choosing to work with a company that can provide high-quality elastomeric products. This is where Global Elastomeric Products can help.

Get Quality Elastomers With Global Elastomeric Products

There are plenty of oilfield equipment suppliers available who can provide elastomeric products, but you need the right one to provide consistent quality every time. Working with multiple suppliers may cost you time and money figuring out which product or service is most reliable, and choosing a poor-quality supplier can cost you dearly in productivity. Global Elastomeric Products is here to help.

When you select Global Elastomeric Products, you choose a company with over 50 years of experience in the industry. We provide packer cups, custom rubber products, drilling machine parts and other critical items for your business, along with custom rubber products for your unique needs. No matter what your company requires, Global Elastomeric Products can provide it all.

Contact Global Elastomeric Products today for a free quote on rubber products. Discover how Global Elastomeric Products can be the only oilfield equipment supplier you'll ever need. Get a free quote on packer cups, oil well casings or any other product in our extensive industry. We can even provide information about our custom rubber products. Learn more about elastomers and the elastomeric products Global Elastomeric Products provides by contacting us today.